Landmark returns - Shaft tower lifted in Freiberg

- 11/15/2021

Freiberg - After the winding tower of the Reiche Zeche training and research mine in Freiberg, which was erected in the 1950s, had been dismantled and excavated in a spectacular operation in the spring, the new winding tower and the inclined strut support were lifted into place in an equally sensational manner on November 3. The remaining components, such as the rope sheave platform, rope sheaves and walkway equipment, could not be lifted in until November 6 due to the extreme weather conditions. With the lifting of the replacement headframe, the project commissioned by TU Bergakademie Freiberg has reached its climax. In 2019, MMG Mitteldeutsche Montan GmbH was awarded the contract for the design and construction supervision of the project. In November 2020, the consortium consisting of SCHACHTBAU NORDHAUSEN GmbH, SCHACHTBAU NORDHAUSEN Bau GmbH and SCHACHTBAU NORDHAUSEN Stahlbau GmbH was finally entrusted with the execution of the reconstruction and refurbishment. In the project with a contract volume of 2.5 million euros, as many components as possible were to be refurbished and reinstalled, while all others were to be replaced identically.

As early as the end of October, the individual units of the winding tower were transported from Nordhausen to Freiberg, where the inclined strut support, which had been rehabilitated on site, was stored.

Under the supervision of the project managers from Schachtbau Nordhausen and MMG, Knut Große and Undine deBortoli, as well as Frank Malchau, who was responsible for the steel construction work, the 26 m long inclined strut support was also put back in place on November 3. As this was still in good condition structurally, it could be refurbished and then reinstalled. Due to the bad weather conditions, however, the lifting of the rope sheave platform, the rope sheaves and the walkway rods, which had been planned for the next day, had to be postponed to November 6. On Saturday afternoon, in perfect weather conditions, the remaining components of the headframe were returned to the site: after the rope sheave platform and the rehabilitated rope sheaves had been installed, the walkway systems could also be attached to the headframe in a final step.

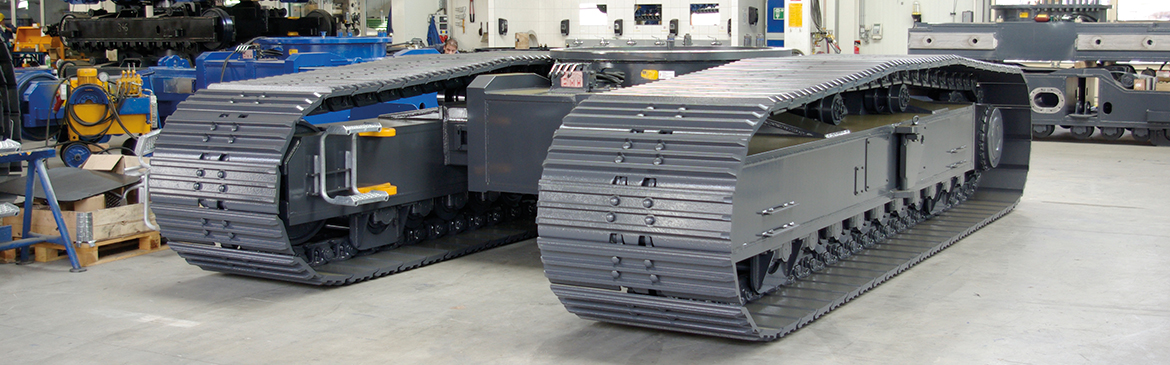

In the past six months, the headframe, the shaft girders, the rope sheave platform and the walkways were manufactured in the production halls of SCHACHTBAU NORDHAUSEN Stahlbau GmbH under the supervision of Frank Malchau. More than 4,500 bolts ensure the cohesion of the conveyor frame, which weighs approx. 34 tons. Each of these bolts, as well as numerous seals, had to be pre-treated and pre-painted by hand in the corrosion protection hall in the next step. Only then could the entire steel structure be painted in four coats with a 300 µm total dry film coating. The painters were therefore busy coating the headframe for several months.

On October 25, the steel colossus then set off for Freiberg, where the surface structures of the Reiche Zeche mining complex had already been reinstalled with the aid of complex crane technology. In September, the two new shaft girders were first lifted into place as a complex steel frame. Heavy crane technology maneuvered the 6.5 ton steel construction element over the opened roof into the shaft hall. It was now followed by the winding tower, the heart of the plant. With the partially refurbished and reconstructed headframe, the Freiberg region regained its landmark after six months.

Until the end of the year, finishing work will now be carried out in and on the shaft building. With the completion of the rehabilitation work on the surface installations, the first phase of the extensive shaft rehabilitation has been completed. Over the next few years, TU will also continue the rehabilitation of the mine underground in cooperation with Schachtbau. SCHACHTBAU NORDHAUSEN GmbH also has a long-standing partnership with the university and currently employs 19 staff (8.8% of the workforce) who successfully completed their studies at the TU Bergakademie Freiberg and have now been able to contribute their knowledge to the prestigious project.

German

German